MS Series – Cartridge Seals

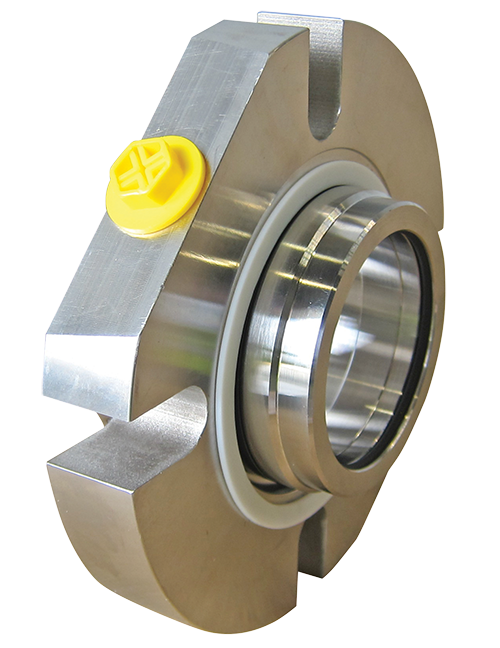

The Aquaplus cartridge seal is a robust, general purpose, bi-directional, multi-spring cartridge mechanical seal designed for the sealing requirements of rotary shaft equipment.

The seal is an hydraulically balanced cartridge seal with protected multi-springs and operates with cooler running faces, longer life and at higher temperatures.

- Features

- Applications

- Technical

- Downloads

- cartridge design

- easy installation

- balanced seal faces

- springs isolated from the process liquid

- static o-ring pump shaft/sleeve

- no fretting

- full face gland

- water

- chemicals

- oils

- fuel oils

- slurries

- sludges

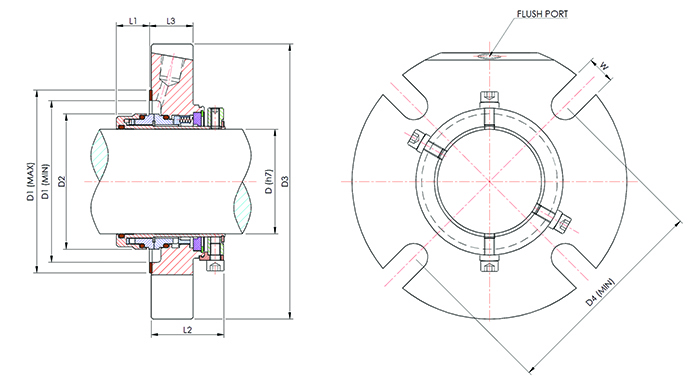

| D Shaft ID |

D1 Stuffing Box ID |

D2 | D3 | l1 | l2 | l3 | W | PCD (D4) | Flushing Port Size | |||||||||||

| inch | mm | MIN | MAX | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | |||

| 24 | 40 | 46 | 41 | 105 | 18.35 | 44 | 26 | 12 | 70 | 3/8″ BSP-f | ||||||||||

| 1.000 | 25 | 1.570 | 40 | 1.850 | 47 | 1.535 | 39 | 3.937 | 100 | 0.650 | 16.5 | 1.732 | 44 | 0.984 | 25 | 0.47 | 12 | 2.756 | 70 | 3/8″ BSP-f |

| 1.125 | 28 | 1.690 | 43 | 1.970 | 50 | 1.693 | 43 | 4.016 | 102 | 0.650 | 16.5 | 1.732 | 44 | 0.984 | 25 | 0.47 | 12 | 2.953 | 75 | 3/8″ BSP-f |

| 30 | 44 | 53 | 44 | 102 | 17 | 44 | 25 | 12 | 78 | 3/8″ BSP-f | ||||||||||

| 1.250 | 32 | 2.010 | 51 | 2.170 | 55 | 1.929 | 49 | 4.134 | 105 | 0.669 | 17 | 1.732 | 44 | 0.984 | 25 | 0.47 | 12 | 3.071 | 78 | 3/8″ BSP-f |

| 33 | 50 | 55 | 50 | 105 | 17.5 | 44 | 25 | 12 | 78 | 3/8″ BSP-f | ||||||||||

| 1.375 | 35 | 2.010 | 51 | 2.280 | 58 | 1.929 | 49 | 4.724 | 120 | 0.689 | 17.5 | 1.732 | 44 | 0.984 | 25 | 0.47 | 12 | 3.228 | 82 | 3/8″ BSP-f |

| 1.500 | 38 | 2.362 | 60 | 2.560 | 65 | 2.185 | 55.5 | 5.039 | 128 | 0.728 | 18.5 | 1.732 | 44 | 0.984 | 25 | 0.47 | 12 | 3.504 | 89 | 3/8″ BSP-f |

| 40 | 60 | 65 | 57 | 128 | 18.5 | 44 | 25 | 12 | 89 | 3/8″ BSP-f | ||||||||||

| 1.625 | 2.375 | 2.560 | 2.185 | 5.039 | 0.728 | 1.732 | 0.984 | 0.47 | 3.504 | 3/8″ BSP-f | ||||||||||

| 42 | 63 | 68 | 58 | 128 | 18.5 | 44 | 25 | 12 | 89 | 3/8″ BSP-f | ||||||||||

| 43 | 63 | 68 | 60 | 128 | 18.5 | 44 | 26 | 12 | 92 | 3/8″ BSP-f | ||||||||||

| 1.750 | 45 | 2.500 | 70 | 2.950 | 75 | 2.437 | 61.9 | 5.000 | 127 | 0.728 | 18.5 | 1.732 | 44 | 0.984 | 25 | 0.47 | 12 | 3.819 | 97 | 3/8″ BSP-f |

| 1.875 | 48 | 2.625 | 71 | 2.950 | 75 | 2.563 | 65.1 | 5.118 | 130 | 0.728 | 18.5 | 1.732 | 44 | 0.984 | 25 | 0.47 | 12 | 3.819 | 97 | 3/8″ BSP-f |

| 2.000 | 50 | 2.795 | 71 | 2.950 | 75 | 2.677 | 68 | 5.827 | 148 | 0.728 | 18.5 | 1.732 | 44 | 0.984 | 25 | 0.47 | 12 | 3.898 | 99 | 3/8″ BSP-f |

| 53 | 75 | 85 | 72 | 168 | 19 | 44 | 25 | 12 | 109 | 3/8″ BSP-f | ||||||||||

| 2.125 | 2.875 | 3.125 | 2.811 | 5.906 | 0.748 | 1.732 | 0.984 | 0.63 | 4.331 | 3/8″ BSP-f | ||||||||||

| 55 | 75 | 77 | 72 | 148 | 19 | 44 | 25 | 16 | 110 | 3/8″ BSP-f | ||||||||||

| 2.250 | 3.000 | 3.250 | 2.937 | 6.220 | 0.748 | 1.732 | 0.984 | 0.63 | 4.250 | 3/8″ BSP-f | ||||||||||

| 2.375 | 60 | 3.228 | 82 | 3.740 | 95 | 3.071 | 78 | 6.220 | 158 | 0.748 | 19 | 1.732 | 44 | 0.984 | 25 | 0.63 | 16 | 4.843 | 123 | 3/8″ BSP-f |

| 2.500 | 63 | 3.275 | 86 | 3.620 | 92 | 3.311 | 84.1 | 6.496 | 165 | 0.748 | 19 | 1.811 | 46 | 0.984 | 25 | 0.63 | 16 | 4.921 | 125 | 3/8″ BSP-f |

| 2.625 | 65 | 3.465 | 88 | 3.660 | 93 | 3.150 | 80 | 6.929 | 176 | 0.768 | 19.5 | 1.811 | 46 | 0.984 | 25 | 0.63 | 16 | 4.921 | 125 | 3/8″ BSP-f |

| 2.750 | 70 | 3.661 | 93 | 3.940 | 100 | 3.228 | 82 | 6.929 | 176 | 0.768 | 19.5 | 1.811 | 46 | 0.984 | 25 | 0.63 | 16 | 5.315 | 135 | 3/8″ BSP-f |

| 2.875 | 3.875 | 4.170 | 3.346 | 7.402 | 0.866 | 1.811 | 1.102 | 0.63 | 5.512 | 3/8″ BSP-f | ||||||||||

| 3.000 | 75 | 4.016 | 102 | 4.170 | 106 | 3.346 | 85 | 7.402 | 188 | 0.866 | 22 | 1.811 | 46 | 1.102 | 28 | 0.73 | 18.5 | 5.512 | 140 | 3/8″ BSP-f |

| 3.125 | 80 | 4.213 | 107 | 4.450 | 113 | 3.425 | 87 | 7.874 | 200 | 0.866 | 22 | 1.811 | 46 | 1.102 | 28 | 0.73 | 18.5 | 5.709 | 145 | 3/8″ BSP-f |

| 3.250 | 4.375 | 4.687 | 3.543 | 8.189 | 0.925 | 1.811 | 1.220 | 0.73 | 6.102 | 3/8″ BSP-f | ||||||||||

| 3.375 | 85 | 4.409 | 112 | 4.720 | 120 | 3.543 | 90 | 8.189 | 208 | 0.925 | 23.5 | 1.811 | 46 | 1.220 | 31 | 0.73 | 18.5 | 6.220 | 158 | 3/8″ BSP-f |

| 3.500 | 90 | 4.606 | 117 | 4.920 | 125 | 3.622 | 92 | 8.661 | 220 | 1.024 | 26 | 1.811 | 46 | 1.220 | 31 | 0.73 | 18.5 | 6.457 | 164 | 3/8″ BSP-f |

| 3.625 | 4.750 | 5.062 | 3.701 | 8.661 | 1.024 | 1.811 | 1.220 | 0.73 | 6.457 | 3/8″ BSP-f | ||||||||||

| 3.750 | 95 | 4.803 | 122 | 5.120 | 130 | 3.701 | 94 | 8.661 | 220 | 1.024 | 26 | 1.811 | 46 | 1.220 | 31 | 0.73 | 18.5 | 6.575 | 167 | 3/8″ BSP-f |

| 3.875 | 5.000 | 5.312 | 4.937 | 1.024 | 1.811 | 1.220 | 0.73 | 6.575 | 3/8″ BSP-f | |||||||||||