PC Series

The Aquaplus PC Series range of pumps is available in a range of versions, sizes and materials to suit a variety of applications. PC Series pumps can pump almost anything from water to shear-sensitive fluids to viscous, corrosive, abrasive and solid-laden fluids.

N Range

The industrial N Range is the ideal pump for arduous and demanding applications. Made of heavy duty construction and utilising a solid shaft with double sealed universal joints the pumps offer high reliability and long service life. Standard pumps are designed to work against differential pressure of up to 24 bars.

W Range

The widethroat W Range is designed to handle highly viscous fluids with viscosity up to 1,000,000 cp. It has a standard open throat hopper and an auger assembly which steadily conveys heavy material from the open throat to the rotor/stator elements. The pumps are run at relatively low speeds which facilitates handling of difficult to flow and shear sensitive products with minimal damage.

F Range

The hygienic F Range of pumps is specifically developed for the food, pharmaceutical and hygienic industries where product integrity is critical. All metallic parts in contact with the fluid are in smooth finish stainless steel. The pump is designed to eliminate any retaining pockets which can cause product contamination. All sizes are available with CIP options. The pumps have open universal joints for fluid having good lubricating properties, while for non-lubricating fluids the pumps are supplied with fail-safe double sealed universal joints jacked with non toxic lubricant.

- Features

- Applications

- Curves

- Tech Specs

- Downloads

- Capacity is proportional to speed

- Head independent of pump speed

- Self priming

- Low NPSH requirement

- Can handle high viscosity materials

- Handles solids in suspension or fluids containing high percentage of solids

- Minimal damage to shear sensitive products

- Reversible

- Non-pulsating flow

- Water and waste water treatment – sludges, dosing, floculants, water, industrial effluents, sewage

- Mining and construction – dewatering, drilling mud, mineral processing, sludge, explosive slurries, grouting

- Cosmetics and pharmaceuticals – lotions/creams, shampoo, glucose, medical formulations, toothpaste, soap and detergents

- Marine – fuel, transfer, seawater, bilge pumping, oil rig

- Food and beverage – sugar syrup, edible oils, confectionery, chocolates, dairy, fruit pulp and juices, winery

- Paper and ceramics – paper, latex, ceramic/clay slip, chemical dosing, starch, paper pulp & cellulose

- Chemicals – fuel oils, organics, dyes/resins, emulsions

| Model Number | Max. Capacity (m³/hr) | Max. Pressure (bar) |

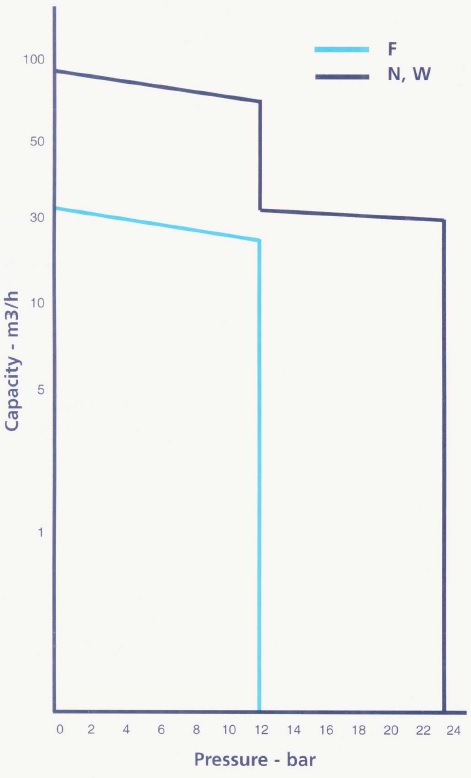

| N 01 | 1.3 | 9 |

| N 02 | 2.9 | 24 |

| N 03 | 10 | 24 |

| N 04 | 15.2 | 24 |

| N 05 | 22.8 | 24 |

| N 06 | 35 | 24 |

| N 07 | 48 | 12 |

| N 08 | 61.5 | 12 |

| N 09 | 86 | 12 |

| N 10 | 95 | 12 |

| W 01 | 1.3 | 9 |

| W 02 | 2.9 | 24 |

| W 03 | 10 | 24 |

| W 04 | 15.2 | 24 |

| W 05 | 22.8 | 24 |

| W 06 | 35 | 24 |

| W 07 | 48 | 12 |

| W 08 | 61.5 | 12 |

| W 09 | 86 | 12 |

| W 10 | 95 | 12 |

| F 01 | 1.3 | 9 |

| F 02 | 2.9 | 24 |

| F 03 | 10 | 24 |

| F 04 | 15.2 | 24 |

| F 05 | 22.8 | 24 |

| F 06 | 35 | 12 |